Winemaking is a non-sterile process and the role of yeast in fermentation is essential to the production of the fermented alcoholic beverages. Wine fermentation is a complex microbiological process in which specific yeasts strains are selected to obtain the desired fermentation characteristics – flavor and aroma – in the final product. Saccharomyces cerevisiae is the main microorganism involved, due to their fast fermentation rates and ability to survive in the harsh environmental conditions of wine.

However, some microorganisms such as lactic and acetic bacteria and yeasts tend to proliferate while the fermentation process is undergoing or in the finished wines and beverages under certain conditions, spoiling them.

Spoilage yeasts growth can affect the chemical production of the wine, generating unpleasant taste and flavors, alter appearance and a reduced shelf life of the product. The presence of spoilage yeasts can generate high economic losses and impact in the brand image.

Amongst contaminants, the yeasts Bretanomyces/Dekkera bruxellensis and Zygosaccharomyces bailii are considered the most dangerous and present spoilage microorganism having been reported in many beverages-producing industries. Zygosaccharomyces bailii contamination occurs mainly in sweet wines or grape juice concentrate, whereas Bretanomyces/Dekkera bruxellensis spoilage often in red and white wines.

Spoilage yeasts: Brettanomyces and Zygosaccharomyces

Brettanomyces yeasts are described as being the teleomorphic state of Dekkera organism which are commonly found in fermentative environments, especially in wines (red and white wine), beers and juices. Its presence in fermented beverages can have a significant impact on the quality and final flavor of these products (Jiminez et al., 1999).

Described as being slow growing, this very adaptable organism responds well to environmental factors. It is capable of surviving in adverse conditions such as low oxygen levels and high alcohol content and is resistant to many of the common contamination control methods used in the production of fermented beverages (Cianni et Comitini, 2014).

D. bruxellensis is known for its ability to produce high quantities of acetic other undesirable compounds like aromatic and phenolic compounds, including 4-ethylguaiacol (4-EG) and 4-ethylphenol (4-EP), that can significantly affect the final flavor and aroma of products. In small quantities, these compounds can provide complexity and depth to the flavors of fermented beverages, but in excess, are responsible for the unpleasant odor and taste, often associated to a leather, horse sweat, and wet hay notes (Bennet, 2016).

Origin of contamination by Bretta in fermented beverages may be vast, but generally occurs during the production environment. The wild yeasts, including Brettanomyces, may be present on the skin of fruits (coming into contact with the wort) and persisting in alcoholic fermentation, on the surface of equipment, or they may be introduced through contaminated raw materials or additives.

Furthermore, one of the main sources of contamination by Brettanomyces is the reuse of wooden barrels or other containers that were previously used for aging alcoholic beverages. Brettanomyces can establish itself in the walls of wooden barrels, and if not properly cleaned and disinfected, can contaminate subsequent beverages stored in these containers.

Due to its resistance and ability to produce aromatic compounds, the presence of D. bruxellensis can be a concern for producers of fermented beverages. Therefore, it is important for producers of fermented beverages to take preventive measures to minimize contamination by Brettanomyces during production, including adopting rigorous practices of hygiene and disinfection, regular monitoring of the presence of unwanted yeasts.

Regarding the yeast Zygosaccharomyces bailii, this microorganism is widely distributed and commonly found in various fermented foods and beverages, including wine, beer, cider, and fruit juices. It is known for its ability to survive and grow in high-acid, high-sugar, and low-oxygen environments, being most often associated with food spoilage and foodborne illness (Moss, 1999).

Key features that make this yeast particularly effective regarding spoilage is its resistance to weak-acid preservatives (e.g., acetic, benzoic and sorbic acids), osmotolerance, high ethanol tolerance and the ability to vigorously ferment glucose (James et Stratford, 2011).

During fermentation, Z. bailii produces acetic acid, ethanol, and other organic acids, which can lead to off-flavors and spoilage in food products. It is also capable of producing biogenic amines, which are compounds that can cause adverse health effects in some individuals (James et Stratford, 2011).

Like Brettanomyces, the origin of contamination by Zygosaccharomyces bailii in fermented beverages generally occurs when the yeast is in the surfaces of fruits and vegetables and can be introduced into the production process through contaminated raw materials or equipment.

The yeast is particularly problematic in the wine industry, where it can survive in wine barrels and cause spoilage even after the barrels have been thoroughly cleaned and sanitized. This yeast can form biofilms on the surfaces of equipment, making it difficult to remove through conventional cleaning methods. Once established, the biofilm can act as a reservoir of yeast cells that can contaminate subsequent batches of product.

Z. bailii has also been found to be resistant to many commonly used preservatives, such as sorbic acid and potassium sorbate, which are typically added to prevent spoilage by other microorganisms. This resistance can allow Z. bailii to thrive in environments where other yeasts and bacteria cannot (Stratford et Capell, 2003).

Therefore, it is important for producers of fermented beverages to take preventive measures to minimize contamination by Brettanomyces and Zygosaccharomyces during production, including adopting rigorous practices of hygiene and disinfection and regular monitoring of the presence of unwanted yeasts. Additionally, detection methods, such as PCR-based techniques, can help identify and mitigate contamination before it leads to spoilage and product loss.

Control of Wine Spoilage

Controlling wine spoilage is an essential part of the winemaking process, as it helps ensure that the final product is safe to consume, has good quality, and maintains its desired flavor profile over time. Wine spoilage can be caused by a range of microorganisms, that can grow during fermentation, storage, and aging.

Winemakers can take several measures to control wine spoilage, such as maintaining strict hygiene practices as described before, but also controlling temperature, pH levels, and using sulfites and other preservatives to prevent the growth of unwanted microorganisms. In addition, they can also use a range of analytical and sensory tests to detect and identify wine spoilage early on, before it becomes too severe.

One of the most important aspects of controlling wine spoilage is preventing contamination from occurring in the first place. This involves besides the properly cleaning and sanitizing winery environment, the carefully of monitoring the grapes and juice to ensure that they are free of spoilage organisms.

During fermentation, winemakers can control the temperature and pH levels to create an environment that is unfavorable to spoilage microorganisms. This can be achieved by carefully monitoring the temperature and pH, using temperature-controlled fermentation vessels, and adding acid or other additives to adjust the pH as needed.

Once the wine has been fermented and aged, winemakers can use a range of analytical and sensory tests to detect and identify wine spoilage, such as chemical analysis, microbiological testing, and sensory evaluation. By identifying spoilage early on, winemakers can take corrective action to minimize the impact of spoilage and salvage the wine if possible.

Regarding the microbiological testing, some facilities may perform what is called the sterility check – is a quality control process that involves testing wine samples for the presence of viable organisms growing on equipment or in packaged wine. It serves as confirmation of the success of any antimicrobial steps executed during the packaging process.

The sterility check is typically conducted at various stages of the winemaking process, including after fermentation, before and after bottling, and during aging. By testing the wine at each of these stages, winemakers can ensure that any contamination that may have occurred during the process is detected and addressed before it affects the quality of the final product.

The sterility check is usually performed by means of traditional culture methods. Wine is filtrated and plated into microbiological plates using aseptic technique in a laminar flow chamber cabinet to prevent contamination from other sources. The microbiological plates are then incubated for 10 days, and visual examination and colony counting is conducted at set intervals of the days.

Culture plating methods have limited cost-effectiveness and decision-making value because of their drawbacks. These procedures are also time-consuming, and not specific, and a further identification of contaminant is required.

When a faster, sensitive, and specific method is required there is a solution that have become increasingly popular in recent years. PCR is a molecular biology technique that allows for the rapid detection and identification of microorganisms based on their DNA.

We present our solution, a real time detection kit that provides results faster and in a more reliable way.

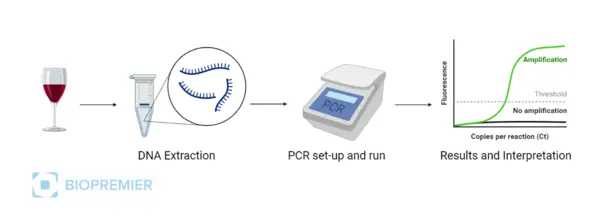

A wine sample is collected, and the DNA of the microorganisms present in the sample is extracted. Then, specific primers and probes are designed to target the DNA of the microorganisms of interest. PCR-based methods offer several advantages over traditional microbiological techniques for sterility checks. With sensitive and specific detection and identification of wine spoilage yeast in 1 day, these extremely accurate kits can be implemented easily into the winery quality control laboratory.

Wine Spoilage Agents Detection

Wine Spoilage Agents detection with Real-Time PCR Kits

- BIOPREMIER (BPMR) kits take full advantage of real-time PCR to enable a quick and reliable method for spoilage organisms’ detection.

- These kits are based on gene amplification and detection using real-time PCR with an DNA-based assay.

- Ready-to-use PCR reagents contain everything required to detect targeted organisms with high sensitivity and specificity.

- The REAL TIME PCR DETECTION TEST KIT beverages Brettanomyces/Dekkera allows the detection of one target, the Brettanomyces/Dekkera fungus.

- The REAL TIME PCR DETECTION TEST KIT beverages Zygosaccharomyces bailii allows the detection of one target, the Zygosaccharomyces bailii fungus.

- All the kits also include an internal control (IC) that allows the exclusion of false negative results.

- Our kits have incorporated a Hot Start polymerase to enable reliable PCR amplification. The mix offers highly reproducible DNA synthesis.

Various tests were performed to ensure both kit quality such as inclusivity, sensitivity, and exclusivity:

- Inclusivity: All target strains tested with the kits were detected corresponding with 100% inclusivity.

- Sensitivity: Sensitivity of 100-1000 CFU/45 mL in wine samples after DNA extraction.

- Exclusivity: More than 30 non-target microorganisms were tested with the kits showed 100% exclusivity with no positive results.

- For DNA extraction, our BIOPREMIER DNA Extraction from Food kit allows efficient extraction and purification of DNA samples from challenging matrices containing high levels of polyphenols. Furthermore, the purified DNA products can be used directly on the PCR.

BPMR presents to you a global solution from the extraction and purification DNA of spoilage yeasts from wine / beverages samples to its detection using our qPCR kits

Important advantages!

- Quick results (one-two days) in few steps: first Fungal DNA Purification, followed by Spoilage Agent Detection and lastly Data Analysis. Check below the “A simple Three-step Protocol”

- Accessible and easy to use thanks to a ready-to-use kits.

- Harmonized protocols for Real Time PCR detection.

- Compatible in the most used real time PCR equipments.

- Includes Positive and Negative PCR controls and Internal control.

Real-Time PCR Solution: A Simple Three-Step Protocol

This flexible and sturdy protocol fits smoothly in any analytical lab workflow to reach the best productivity! Ranges from low to high throughput testing, with simple to use user interface, to, in the end, provide efficient sample interpretation.

Real Time PCR detection test kit Beverages Brettanomyces/Dekkera: click here

Real Time PCR detection test kit Beverages Zygosaccharomyces bailii: click here

References:

- Bennett, L. E. (2016). Spoilage: Yeast Spoilage of Food and Beverages. Elsevier EBooks, 113–117. www.sciencedirect.com

- Ciani, M., & Comitini, F. (2014). Brettanomyces. Elsevier EBooks, 316–323. www.sciencedirect.com

- James, S. W., & Stratford, M. (2011b). Zygosaccharomyces. www.sciencedirect.com

- Jimenez, J. C., Fidalgo, M. A., & Alguacil, M. (1999). BRETTANOMYCES. Elsevier EBooks, 302–308. www.sciencedirect.com

- Moss, M. O. (1999). SPOILAGE PROBLEMS | Problems Caused by Fungi. In Encyclopedia of Food Microbiology. www.sciencedirect.com

- Stratford, M., & Capell, C. J. (2003). SOFT DRINKS | Microbiology. In Encyclopedia of Food Sciences and Nutrition (Second Edition). www.sciencedirect.com